INNOVATIVE GREEN-PERFORMING CONCEPT

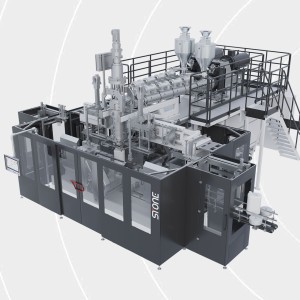

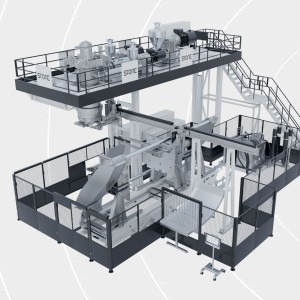

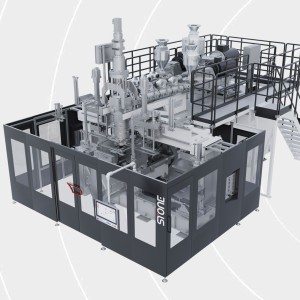

Extrusion Blow Moulding Machines

A complete range of Extrusion Blow-Moulding Machines for Industrial and Consumer Packaging Industries with Green-Performing complete Solutions

The evolution of the production process

Extrusion Blow Moulding Machines

For food & beverage, pharmaceutical and consumer packaging applications plus industrial packaging.

For the production of wide range of applications (including floating solar panels docks) the production of future mobility industry components as CPV and special multi-layers fuel tanks for new Hybrid cars.

Stone consumer packaging machines are available as whole electric, hydraulic and hybrid single and double station - even with multi-cavities moulds - machines for innovative packaging requirements up to roughly 20 litres for standard packaging with and without handle as well as for sterile and multilayer packaging.

Industrial packaging machines are reaching size to produce Jerrycans/Canisters, L-RING drums and IBC containers with fast cycle and best minimum weight performance.

STONE has been built on sturdy pillars

State of the Art Facilities

The new STONE headquarters, located in Shunde/Foshan, China, feature a cutting-edge facility spanning 3,600 square meters.

This modern space encompasses manufacturing, assembly, and testing areas, alongside contemporary office facilities, ensuring optimal operational efficiency.

Expert Leadership

STONE combines European expertise with an elite team of blow moulding professionals. These specialists bring invaluable experience from one of the most prominent BMM industrial hubs, particularly dedicated to continuous extrusion BMM for consumer and industrial packaging sectors.

Global Presence, Local Connection

ST BlowMoulding Group operates through manufactory strategic location in Switzerland, Italy, North America (ST Blow Molding USA), and Asia (STONE).

As we say, "Global is becoming Local". Innovation and Sustainability at the Core.

Following the vision of "Moving Forward, by Your Side", STONE embodies ST's commitment to innovation and sustainability.

Best energy efficiency combined with maximum OEE levels

STONE has an integrated systems approach: seamlessly connecting machines, molds, downstream processes to reduce every consuption.

Focus on waste elimination and product optimization to keep saving resources.

Expert application support to reduce product weight and cycle times.

Enhanced Customer Support

STONE Total Customer Care represents a comprehensive after-sales service approach, offering:

- Fast reaction in remote or proximity trouble-shooting

- Video tutorial & high quality use & maintenance instruction manuals

- Predictive & preventive scheduled maintenance based on continuous process monitoring and on site inspection

- Planned machine inspections

Commitment to Sustainability

STONE enters the market with a clear vision for real business sustainability. Through advanced extrusion technologies, we enable clients to:

- Maximize usage of reclaimed scraps (both industrial and post-consumer)

- Achieve superior ESG policy compliance

- Reduce environmental impact while maintaining premium product quality